Timothy Dale is a seasoned home repair specialist and author, boasting more than ten years of practical experience in construction and home enhancement. His expertise encompasses a wide range of areas, including plumbing, electrical work, carpentry, installation, renovations, and project management in residential, commercial, industrial, and institutional settings.

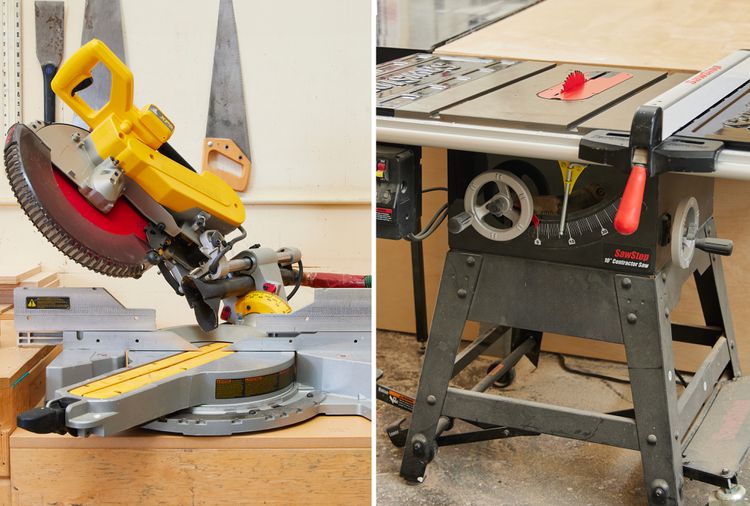

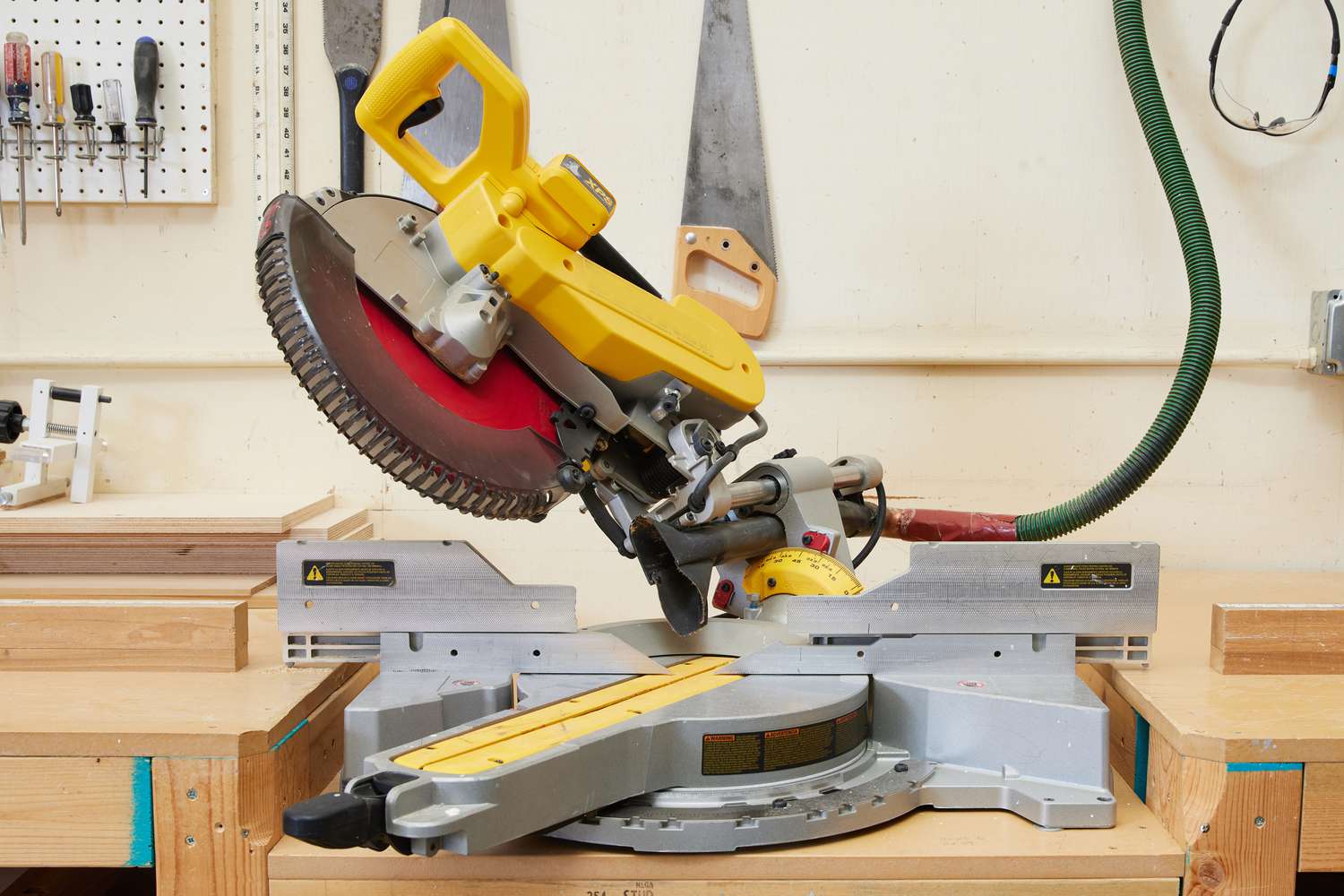

Miter saws feature a compact base located beneath the saw blade, which is mounted on a pivoting arm above. The workpiece is placed on this base, and the user lowers the spinning blade to make precise cuts. In contrast, a table saw is equipped with a broad, table-like base and a blade that extends upward from the center. In this case, the user pushes the material across the blade, rather than the blade moving through the material.

Discover the distinctions between a miter saw and a table saw with this comprehensive guide.

Miter Saw vs. Table Saw: Key Distinctions

Miter saws are designed to perform precise and consistent crosscuts, bevel cuts, and miter cuts, whereas table saws offer a broader range of cutting options, such as rip cuts, crosscuts, bevel cuts, and angled cuts. With a miter saw, you can adjust the saw blade’s position and then lower it directly onto the material. In contrast, table saws are less precise, as the accuracy depends on the operator’s ability to guide the material through the blade.

In general, a table saw is ideal for handling larger materials, such as plywood sheets or lengthy boards, whereas a miter saw is more suited for cutting smaller wood pieces, such as baseboards. Miter saws, however, are more portable, as they can be easily transported in a vehicle. Furthermore, they are usually more affordable and are often more approachable for beginners or those with limited experience in DIY projects.

- More suitable for smaller wood fragments and various other materials.

- Delivers accurate and consistent cuts with exceptional precision.

- Not an ideal option for performing rip cuts on substantial materials.

- Ideal for achieving precise crosscuts.

- Created for producing consistent angled and beveled cuts.

- Convenient for transportability.

- Somewhat adaptable

- Typical expenses range from $300 to $1,000.

- Ideal for handling large panels of wood and various other materials.

- Produces fairly precise cuts in the material.

- Commonly employed for producing lengthy, precise rip cuts.

- Can perform crosscuts with moderate precision.

- Can be utilized for cuts at an angle or with a bevel when equipped with the appropriate attachments.

- Typically secured in position.

- Extremely adaptable

- Typical expenses range from $200 to $5,000.

Miter Saw vs. Table Saw: Dimensions of Materials

Miter saws are perfect for cutting small, slender materials that can rest on their compact base. Typically, these saws feature blades that are between eight and twelve inches wide, and some models include a sliding arm to extend the cutting capacity. While table saws can handle smaller materials, they truly shine when working with longer boards or larger sheets of wood. The material can be pushed into the fixed saw for making both crosscuts and rip cuts.

Miter Saw versus Table Saw: Precision Comparison

The specific degree of precision needed for a project can differ based on the task at hand. For example, achieving a precise angle is crucial when cutting corner trim, whereas cutting deck or fence boards to the correct length is less critical. Generally, a miter saw is regarded as more precise than a table saw, making it the preferred choice for more detailed woodworking tasks.

One aspect that enhances the precision of a miter saw is the reduced likelihood of user mistakes. Once the blade is adjusted and the material is positioned on the base, the user simply needs to lower the spinning blade to cut through the material. In contrast, with a table saw, the user must maneuver the material through the blade, which can impact the cut’s accuracy. Nevertheless, the precision of a table saw can be improved by utilizing guides or jigs.

Miter Saw versus Table Saw: Ripping Techniques

Rip cuts are cuts that run parallel to the grain of the wood, unlike crosscuts, which are made perpendicular to the grain. Miter saws are not suitable for making rip cuts, as their blade angle is not designed for that purpose. A table saw is the preferred tool for achieving long, precise rip cuts along the length of boards or sheets of plywood. To ensure a straight cut, be sure to utilize the rip fence.

Miter Saw versus Table Saw: Making Crosscuts

A crosscut involves slicing through the material’s width. These types of cuts are frequently encountered in DIY woodworking projects, as it is often necessary to trim or shorten planks or boards to achieve the desired dimensions for the task. Miter saws are generally more effective for crosscuts compared to table saws, thanks to the arrangement of the base and the placement of the blade.

Miter saws are designed to perform precise and consistent crosscuts efficiently. While a table saw can also achieve crosscuts, the level of accuracy largely relies on the operator, making it more suitable for single cuts rather than repeated ones. To enhance the precision and stability of crosscuts on a table saw, consider utilizing a crosscut sled or jig.

Miter Saw vs. Table Saw: Cuts at Angles and Bevels

Angled cuts are often referred to as miter cuts, which are cuts made at angles other than 90 degrees. In contrast, bevel cuts are produced by tilting the saw blade to create a sloped edge rather than a flat one. Miter saws, as their name suggests, are specifically designed for making precise miter cuts, making them more suitable than table saws for achieving accurate angles.

Compound miter saws have the capability to execute both angled and bevel cuts simultaneously by modifying the blade’s position. While table saws can also perform angled and bevel cuts with a fair degree of precision, achieving bevel cuts on a table saw can be quite difficult and is generally recommended for more experienced woodworkers.

Miter Saw vs. Table Saw: Ease of Transport

The arm of a miter saw can be secured, allowing the saw, which weighs between 30 and 40 pounds, to be conveniently loaded into the trunk of a vehicle for transport. In contrast, a table saw is much less mobile, often weighing over 200 pounds. Although certain table saw models come with wheeled stands, they are still regarded as less portable compared to miter saws.

Miter Saw vs. Table Saw: Flexibility in Use

Miter saws offer a good level of versatility, enabling hobbyists to perform crosscuts, angled cuts, and bevel cuts with precision. On the other hand, table saws generally provide greater versatility, as they can handle a broader range of cuts, including rip cuts, crosscuts, bevel cuts, and angled cuts, among others. Additionally, the functionality of a table saw can be enhanced with the addition of specialized accessories, such as guides or jigs.

Miter Saw versus Table Saw: Price Comparison

Typically, a miter saw is more affordable, making it a suitable option for beginners or those new to DIY projects. On average, a quality miter saw will cost between $300 and $1,000. In contrast, table saws require a larger investment, with prices starting around $200 and going beyond $5,000.

Which is superior, a miter saw or a table saw?

A miter saw and a table saw each have their own advantages and are suited for different cutting tasks, making it difficult to declare one as superior to the other. Miter saws are ideal for precise, consistent crosscuts and angled cuts, whereas table saws are best for making extended, longitudinal rip cuts.

Is it possible to utilize a miter saw in place of a table saw?

Due to the distinct functionalities of these saws, attempting to use a miter saw as a table saw is not advisable. A miter saw features a blade that is positioned above the material and descends to make cuts, whereas a table saw has a blade that is stationary within the table’s base, enabling the user to push the material across the blade.

Is it possible to use a miter saw to cut a 2×4?

A miter saw is certainly capable of cutting through a 2×4, but the size of the saw blade can influence its performance. Blades with a larger diameter can manage bigger pieces of wood, enabling the miter saw to perform crosscuts or angled cuts with ease. However, it’s important to mention that a table saw is proficient at making both crosscuts and rip cuts on 2x4s, making it the preferred option for cutting larger materials.